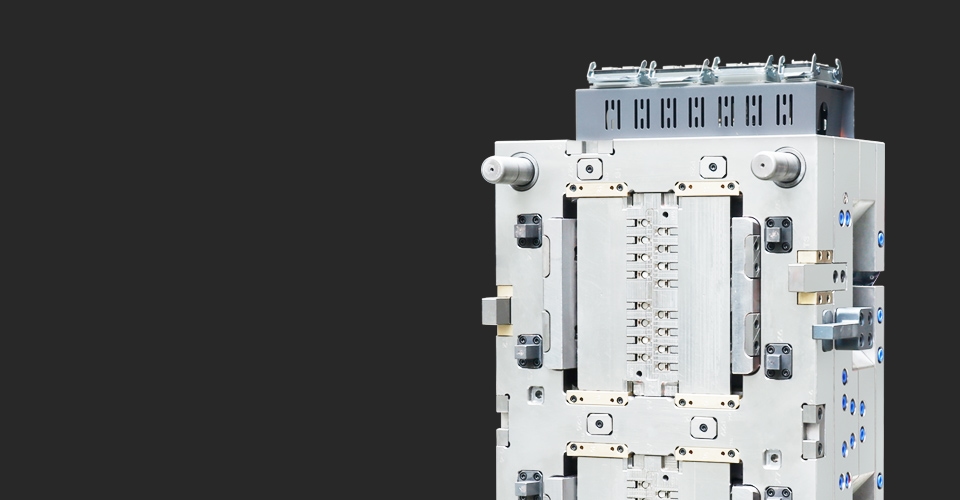

The hum of the injection molding machine, the satisfying thunk as a perfect part is ejected – it’s a symphony of modern manufacturing. But at the heart of this process lies a critical element: the plastic injection molding mold. Choosing the right mold isn’t just a technical decision; it’s a strategic one that can significantly impact your product quality, production efficiency, and ultimately, your bottom line.

Forget flipping through a catalog and pointing at the shiniest option. Selecting the ideal mold requires a deep dive into your specific needs and a nuanced understanding of the factors at play. Think of it as choosing the perfect instrument for an orchestra – each has its purpose, and the wrong one will sound a sour note in your production.

So, how do you navigate this labyrinth and ensure you choose the mold that will conduct your manufacturing symphony flawlessly? Here are the key factors to consider, moving beyond the basic blueprint:

1. The Intricacies of Your Part Design: More Than Just Shape

Your part design is the fundamental starting point, but it’s more than just the aesthetic. Consider:

- Complexity: Intricate geometries, undercuts, thin walls, and tight tolerances will necessitate more complex and often more expensive mold designs. Think about multi-cavity molds with sophisticated ejection systems or even specialized mold actions like slides and lifters.

- Material Selection: Different plastics have varying shrinkage rates, melt temperatures, and flow properties. Your chosen material will directly influence the mold material, gating system, and cooling channel design. A mold designed for polypropylene might not be suitable for high-temperature engineering plastics.

- Surface Finish Requirements: Do you need a glossy, textured, or matte finish? This will dictate the surface treatment of the mold cavities, potentially requiring polishing, texturing, or even specialized coatings.

- Part Size and Weight: Larger and heavier parts will require robust mold construction and potentially larger injection molding machines, impacting mold size and weight considerations.

2. Production Volume: Scaling for Success (and Cost-Effectiveness)

Your anticipated production volume is a major driver in mold selection:

- Low Volume Prototypes or Short Runs: For initial testing or limited production, a simpler, less expensive mold made from softer materials (like aluminum or pre-hardened steel) might suffice. Single-cavity or basic multi-cavity molds are often preferred.

- Medium Volume Production: As your demand increases, you’ll need more durable molds made from hardened steel. Multi-cavity molds become more economically viable to increase output per cycle.

- High Volume Mass Production: For continuous, large-scale production, invest in high-quality, multi-cavity molds made from premium hardened steel. These molds are designed for longevity and minimal maintenance, maximizing efficiency over millions of cycles.

3. The Balancing Act: Budget vs. Longevity and Quality

While cost is always a consideration, remember the adage: you get what you pay for.

- Initial Mold Cost: Cheaper molds might seem appealing initially, but they can lead to higher maintenance costs, shorter lifespan, and potentially lower part quality in the long run.

- Mold Material and Construction: Investing in higher-quality mold materials and robust construction will result in a more durable mold with a longer lifespan, reducing the need for frequent replacements and minimizing downtime.

- Complexity and Features: More complex mold designs with advanced features will naturally cost more upfront but can significantly improve efficiency and part quality, potentially offsetting the initial investment over time.

4. Cycle Time Optimization: Efficiency is Key

The time it takes to complete one molding cycle directly impacts your production output and cost-effectiveness:

- Mold Design and Cooling Channels: Efficient cooling channel design is crucial for reducing cycle times. Well-placed channels that effectively dissipate heat will allow for faster solidification of the plastic.

- Gating System: The design and location of the gates (where plastic enters the mold) can influence fill time and part quality, ultimately affecting the overall cycle time.

- Ejection System: A well-designed ejection system ensures parts are removed quickly and efficiently without damage, minimizing delays in the cycle.

5. The Expertise of Your Mold Maker: A Partnership, Not Just a Transaction

Choosing the right mold maker is just as crucial as choosing the right mold design. Look for:

- Experience and Reputation: A mold maker with a proven track record in producing molds for similar applications and materials is invaluable.

- Design Capabilities: Do they have in-house design expertise and utilize CAD/CAM software to optimize mold design for manufacturability and efficiency?

- Material Knowledge: They should have a deep understanding of various mold materials and their suitability for different plastics and production volumes.

- Communication and Support: A good mold maker will communicate clearly throughout the process, offering technical support and addressing any concerns promptly.

Beyond these core factors, consider:

- Mold Base Standards: Utilizing standardized mold bases can reduce lead times and costs.

- Maintenance and Repair: Inquire about the mold maker’s maintenance recommendations and repair services.

- Future Production Needs: Consider potential future increases in production volume or design modifications when selecting a mold.

The Takeaway: Invest Wisely, Produce Efficiently

Choosing the right plastic injection molding mold is an investment in your product’s success. By carefully considering these key factors and partnering with a knowledgeable and reputable mold maker, you can ensure a mold that delivers precision, reliability, and efficiency for years to come. Don’t just settle for a mold; choose a solution that will be the backbone of your successful manufacturing journey.