In the world of packaging, bottle caps may seem like small components, but their quality and consistency are critical to product safety, usability, and brand reputation. Bottle cap molding machines play an essential role in producing these components with high precision and efficiency. This article explores how these specialized machines optimize plastic cap production, ensuring superior quality while maximizing productivity.

Understanding Bottle Cap Molding Machines

Bottle cap molding machines are designed specifically to manufacture plastic caps through injection molding. They melt plastic resin and inject it into molds shaped like bottle caps. Once cooled and solidified, the caps are ejected, ready for use in various industries such as beverages, pharmaceuticals, and cosmetics.

Precision in Plastic Cap Production

Precision is paramount in bottle cap manufacturing. Caps must fit perfectly on bottles to prevent leaks, contamination, or spoilage. Bottle cap molding machines achieve this precision through:

- High-Quality Mold Design: Advanced molds are engineered with tight tolerances to produce caps with exact dimensions and consistent thread patterns.

- Accurate Temperature Control: Maintaining optimal temperature during injection prevents defects like warping or incomplete filling.

- Consistent Injection Pressure: Uniform pressure ensures the plastic fills every part of the mold, producing flawless caps.

- Automated Quality Monitoring: Many modern machines include sensors and cameras to detect defects in real-time, reducing waste and ensuring only perfect caps move forward.

Efficiency Benefits of Bottle Cap Molding Machines

Efficiency is equally important to meet high production demands. Bottle cap molding machines enhance efficiency by:

- Fast Cycle Times: Optimized injection and cooling cycles enable rapid production, sometimes producing thousands of caps per hour.

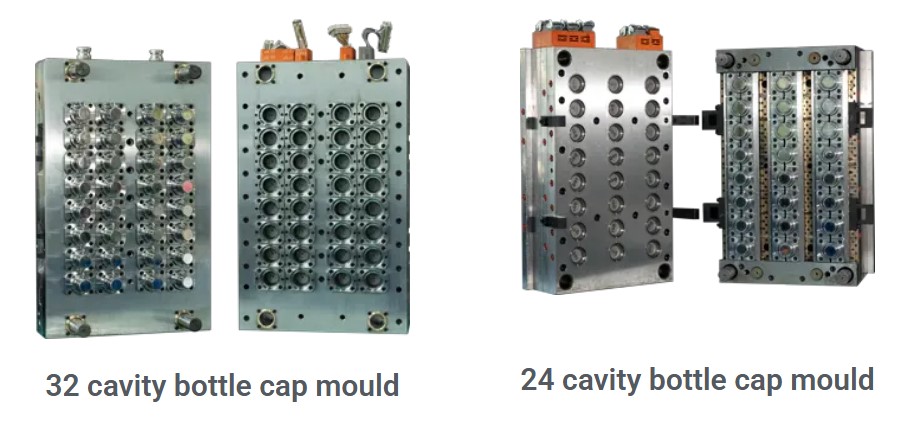

- Multi-Cavity Molds: These molds allow multiple caps to be produced simultaneously, significantly increasing output.

- Energy-Efficient Operation: Modern machines use servo motors and advanced hydraulics to reduce energy consumption.

- Automation Integration: Robotic arms and conveyors streamline handling, packaging, and inspection, minimizing manual labor and errors.

Applications Across Industries

Bottle cap molding machines serve various sectors, including:

- Beverage Industry: Producing caps for water, soda, and juice bottles.

- Pharmaceuticals: Manufacturing tamper-evident and child-resistant caps.

- Cosmetics: Creating aesthetically pleasing caps for lotions and creams.

- Household Products: Making caps for cleaning agents and detergents.

Conclusion

Bottle cap molding machines are vital for producing high-quality plastic caps with unmatched precision and efficiency. By investing in advanced molding technology, manufacturers can ensure product safety, reduce waste, and meet growing market demands with speed and reliability.

Ready to enhance your plastic cap production with cutting-edge bottle cap molding machines? Contact us today to learn more about our solutions tailored to your manufacturing needs!